Per Bach Laursen’s piglets suffered from edema. Various circumstances meant that Per came into contact with the Swedish company Anolytech, something that would prove to be a stroke of luck. Today, medicine consumption at Lundgården is greatly reduced.

Lundgården is located right next to the Limfjord in northern Jutland and has been owned by the family since 1939. The dairy cows accounted for the largest turnover on the farm until 1983. This was followed by a few years when the farm was run without animals. In 1990, Per Bach Laursen joined the company as a partner with his parents. At the same time, he worked as a cow feed salesman at a Danish feed company.

– It was interesting with cows, but I saw that my colleague who sold pig feed had much more fun than me. His customers were more driven and they drove Volvo. My customers drove Opel, says Per a bit jokingly.

Several buildings at Lundgården were empty and when a business plan was drawn up, it was clear that the company needed a larger turnover.

– I did not know much about pigs, but the bank liked the proposal that we should invest in pig breeding, says Per. Said and done, they invested in 300 sows in the early 90’s and since then the business has grown to today’s 1,200 sows in production. Since 1998, Per Bach Laursen has been the sole owner of the company.

Question mark

In 2008, the most recent expansion took place, from 600 to 1,200 sows.

– In the beginning it went well and everything flowed, but at the end of 2010 we had a violent outbreak of edema, says Per and continues:

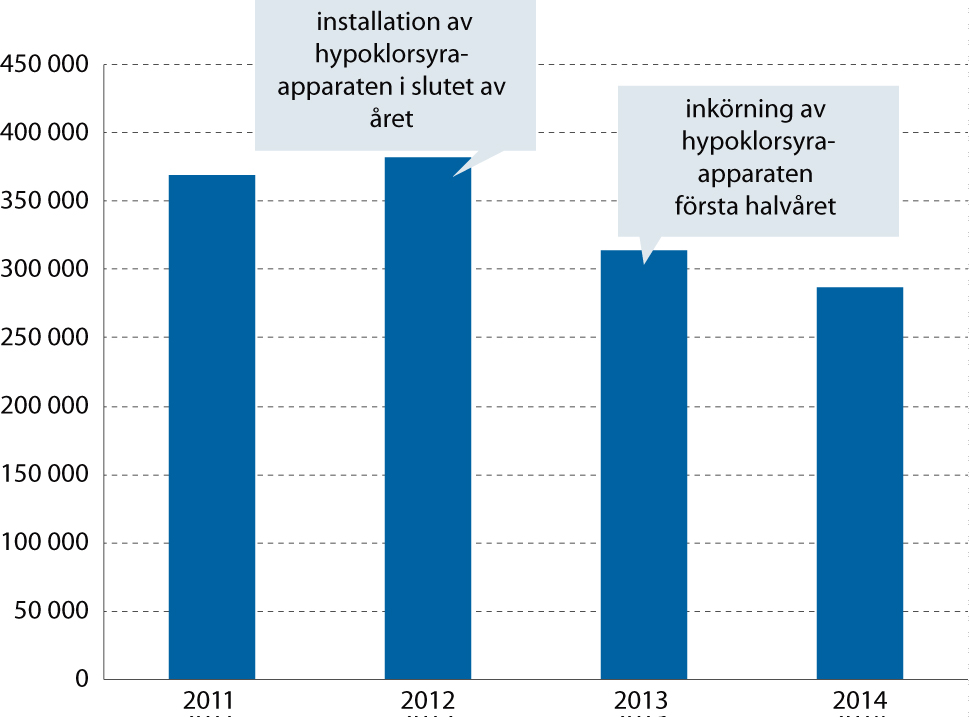

– We had new fresh stables with good production and then suddenly the pigs get really sick. We all stood as question marks and I could not really let go of the thought of what caused the outbreak. Initially, the symptoms were alleviated with the help of an autovaccine, a herd-specific vaccine produced with the help of the pigs’ own bacteria. But it was both awkward and very expensive. Other drug consumption also soared in 2011.

– It was just the opposite of how I want to run a farm, Per adds.

Meeting by chance

Shortly after the outbreak of the disease, Per was asked by a colleague in politics if he wanted to attend a company meeting, as an expert in Danish pig breeding.

– I said yes and we met the Swedish company Anolytech, says Per. Anolytech provides devices that produce hypochlorous acid, Anolyte-PCTM, via water, salt and electricity, which has a disinfectant effect.

– I was fascinated by the function of the device and of Anolyte-PCTM, but it was not until Anolytech visited Lundgården a little later that I was struck by the probable cause of the outbreak of edema. We had stopped fermenting the feed, says Per. Per’s theory is that the bacterial flora in the wet food has become unfavorable for the piglets, something that has previously been possible to counteract via fermentation.

– I decided right away. If Anolytech could ensure easily accessible service on the device in Denmark, I would buy it, says Per.

The installation

At the end of 2012, the machine was installed, and shortly afterwards it was put into use.

– It was quite exciting, laughs Per and explains:

– We had been instructed to introduce Anolyte-PCTM in the water pipes successively for two months. The reason for this is that all water pipes have more or less biofilm on the inside and if you increase the dosage too quickly, the entire film loosens at once. It will be a shock both for the pigs and for the water nipples, which can be blocked. But we were a little impatient, so in a month we were up in full dose. The stable staff were frustrated, they did nothing but clean water nipples for days on end, but at the same time we had received a receipt that the agent had actually achieved something in the pipes.

Low cost

Gradually, it has now been possible to reduce the consumption of medicines, which consisted of both Tylan in the feed and other medicines.

– At first I did not dare to believe that it was true, but since the spring of 2014 we have a stable low medicine consumption, says Per. He has invested SEK 250,000 in the device itself. The consumables consist of salt and electricity.

– It costs so little that I do not even know the number, says Per. On the other hand, they have saved a lot of money on reduced medication use and on disinfectants, because they now use hypochlorous acid instead of traditional disinfectants when washing the stables. In addition, Anolyte-PCTM is used in the dimming and cooling systems, as well as in the washing of the wet feed vessel, which takes place before each new mixture.

Work environment issue

The edema disease is gone and the pigs are doing well, but Per believes that the hypochlorous acid may have had a greater effect than that.

– In the summer of 2014, one of the animal keepers was hospitalized. It was found that he had MRSA, which, however, was not the reason for the hospital stay. Attans, now we have MRSA in the pigs, I thought, says Per. However, Per wanted to know for sure, so he decided to have the pigs tested. The test results were negative. The vet had obviously not been infected by Per’s pigs, nor had the pigs infected the vet.

– We have Anolyte-PCTM in the entire stable environment, I think it is positive, says Per, who attributes part of the credit to the product because the test results were actually negative. However, Per does not know if the crew has always been free of MRSA, as this was the first time the matter was investigated.

– I see MRSA as an important work environment issue. I will take samples of my herd continuously in the future, and if the test results are positive, we must make sure to keep the infection inside the stable walls, Per concludes.

The original article is written by Jordbruksaktuellt, see their articles here: https://www.ja.se/artikel/47372/lundgarden-valde-en-alternativ-vag-till-sankt-medicinforbrukning.html?fbclid=IwAR3Wy-f8muvvOsQ18Xy7bug2Yd-FY5GH-NmHAj0qBRxDsF_p